Software

Learn more about the possibilities of ClaRa+:

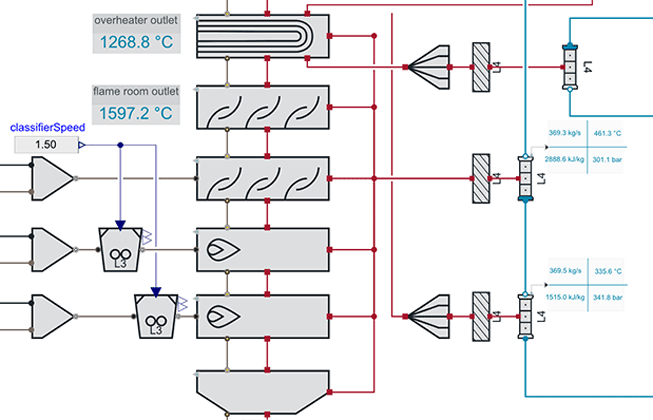

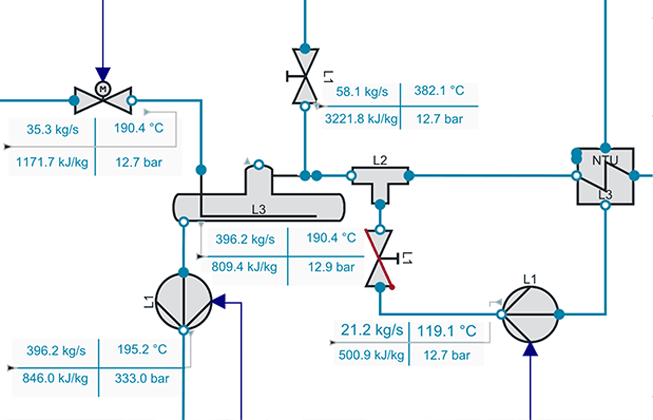

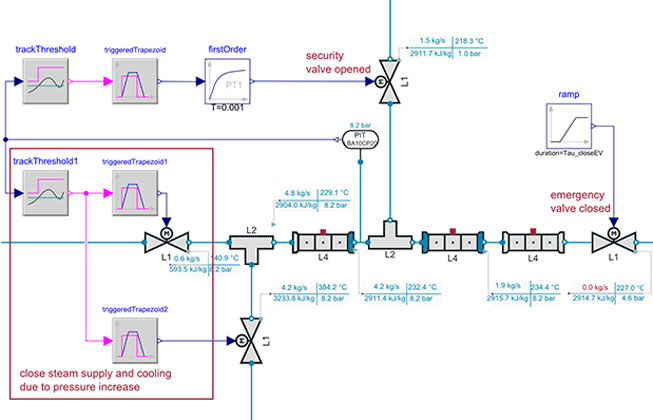

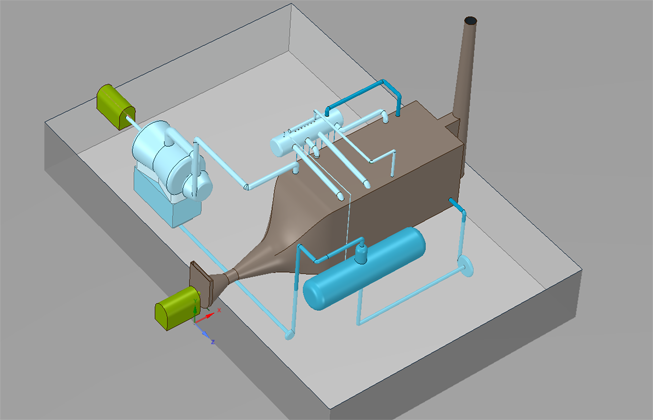

Create a digital twin of your power plant, investigate transient behavior and gain greater understanding to optimize your processes for use in the future energy market. Use ClaRa+ to support all project phases - from evaluation of concept variants to component design, optimization of control technology, virtual commissioning and optimization during operation.

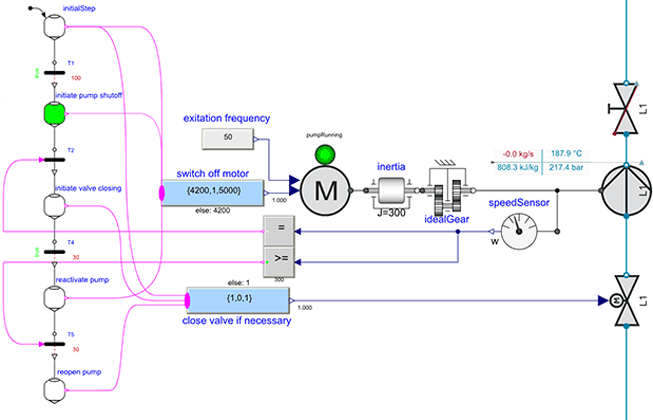

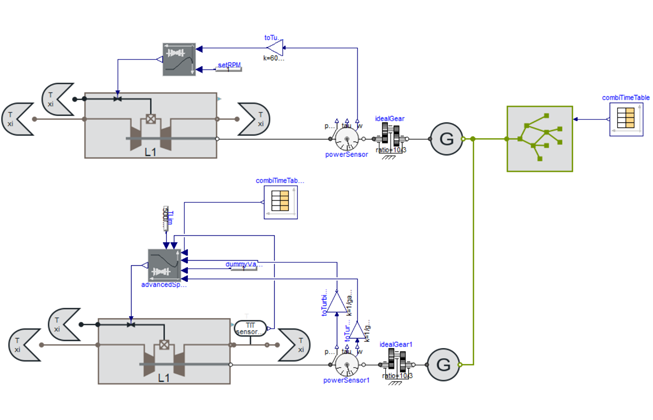

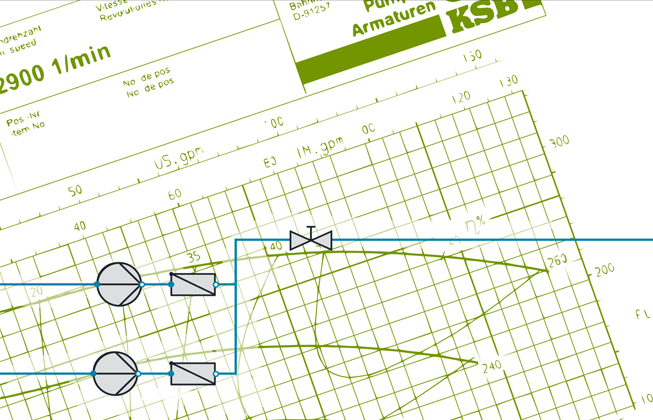

ClaRa+ is a library of power plant components programmed in the Modelica model description language. It enables users to dynamically simulate power plants and answer current questions concerning power plant operation. Dymola software is used for translation and simulation and as the main development environment.

Are you interested in our product? Write us an e-mail. We would be happy to provide you with information.

E-MailWould you like to test our product? You can download a demo version of ClaRa+ that has a reduced scope.

Services

As experts in modeling and simulating power plants and complex energy systems, we would be pleased to help you answer your questions.

Simulation studies

Are you interested in our services? Write us an e-mail. We would be pleased to provide you with information.

Training & Support

XRG Simulation GmbH and TLK-Thermo GmbH offer training and support packages that enable you to start modeling power plant processes with ClaRa/ClaRa+.

References

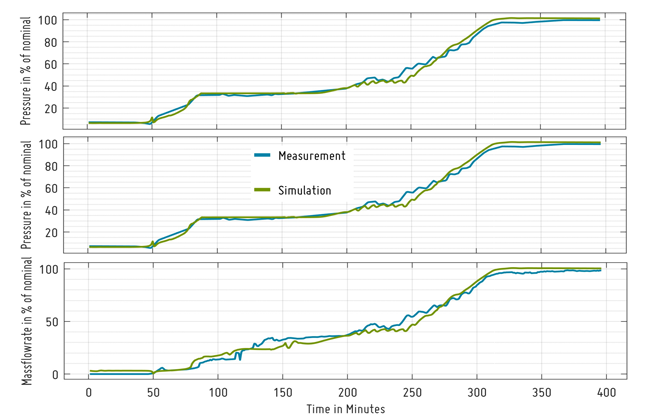

ClaRa+ and demo version ClaRa, available under Modelica license version 2.0, are used by more than 50 users worldwide. Learn more about some selected success stories below:

Downloads

Download ClaRa now!

The free demo version ClaRa gives a good overview of the possibilities of power plant simulation and enables conceptional studies. The commercial version ClaRa+ offers extra content, is more user-friendly and supports the component design due to precise detail models. For translation, simulation and as a main development environment, we recommend commercial software Dymola.

Download ClaRaClaRa+ brochures

- Flyer Software // Download (pdf)

- Flyer Services // Download (pdf)

- Training description // Download (pdf)

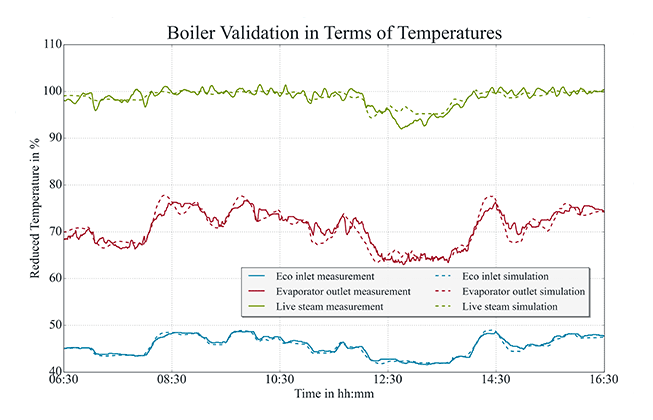

- „ClaRa+ Quality Management: On Validation of Implemented Physics“ // Download (pdf)

- „ClaRa+ Quality Management: Efforts for Certification According to ISO 9001:2008“ // Download (pdf)

- Presentations ClaRa User Meeting from June 4th, 2019 // Download (zip)

Publications

- [1] Johannes Brunnemann , Friedrich Gottelt, Kai Wellner, Ala Renz, André Thüring, Volker Röder, Christoph Hasenbein, Christian Schulze, Gerhard Schmitz, Jörg Eiden: „Status of ClaRaCCS: Modelling and Simulation of Coal-Fired Power Plants with CO2 capture“, 9th Modelica Conference, München, 2012 // Download (pdf)

- [2] Volker Roeder, Christoph Hasenbein, Alfons Kather, Kai Wellner, Gerhard Schmitz, Johannes Brunnemann, Friedrich Gottelt, Ala Renz, Christian Schulze, André Thüring: „Das Projekt DYNCAP: Untersuchung des dynamischen Verhaltens von Dampfkraftprozessen mit CO2-Abtrennung zur Bereitstellung von Regelenergie“, Proceedings of the 44th Conference on Power Plant Technology, Dresden, Oktober, 23–24, 2012

- [3] Alfons Kather, Volker Roeder, Christoph Hasenbein, Gerhard Schmitz, Kai Wellner, Friedrich Gottelt, Lasse Nielsen: „DYNCAP Dynamische Untersuchung von Dampfkraftprozessen mit CO2-Abtrennung zur Bereitstellung von Regelenergie“, Abschlussbericht, Technische Universität Hamburg-Harburg, TLK-Thermo GmbH, XRG Simulation GmbH, 2015 // Download

- [4] Friedrich Gottelt, Kai Wellner, Volker Roeder, Johannes Brunnemann, Gerhard Schmitz, Alfons Kather: „A Unified Control Scheme for Coal-Fired Power Plants with Integrated Post Combustion CO2 Capture“ Proceedings of the In 8th IFAC Conference on Power Plant Power System Control, Toulouse, Frankreich, 2012 // Download

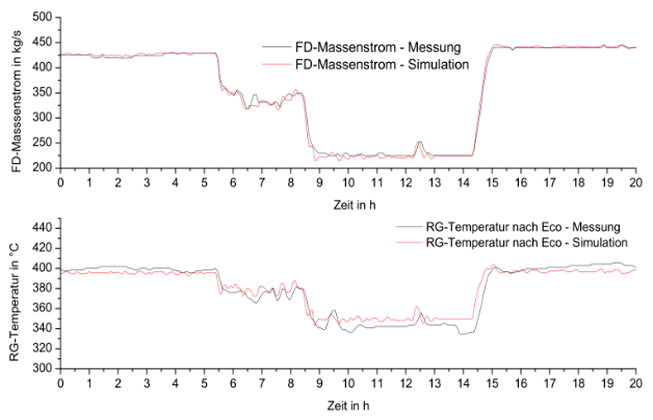

- [5] Marcel Richter, Florian Möllenbruck, Andreas Starinski, Gerd Oeljeklaus, Klaus Görner: „Flexibilization of coal-fired power plants by Dynamic Simulation“ Proceedings of the 11th Modelica Conference, Paris, 2015 // Download (pdf)

- [6] C. Gierow, M. Hübel, J. Nocke, E. Hassel: „Mathematical Model of Soot Blowing Influences in Dynamic Power Plant Modelling“ Proceedings of the 11th Modelica Conference, Paris, 2015 // Download (pdf)

- [7] K. Wellner, T. Marx-Schubach, G. Schmitz: „Dynamic Behavior of Coal-Fired Power Plants with Postcombustion CO2 Capture“ Industrial & Engineering Chemistry Research, 2016 // Download (pdf)

- [8] Friedrich Gottelt, Timm Hoppe, Lasse Nielsen: „Applying the Power Plant Library ClaRa for Control Optimisation“ Proceedings of the 12th Modelica Conference, Prag, 2017 // Download (pdf)

- [9] J. Prause, M. Hübel, D. Holtz, J. Nocke, E. Hassel: „Local steam temperature imbalances of coal-fired boilers at very low load“ Energy Procedia 120, 2017 // Download

- [10] Marcel Richter, Gerd Oeljeklaus, Klaus Görner: „Improving the load flexibility of coal-fired power plants by the integration of a thermal energy storage“, Applied Energy, Volume 236, 15 February 2019, Pages 607-621

- [11] Vojacek, A., Dostal, V., Goettelt, F., Rohde, M., Melichar, T. (February 11, 2019) „Performance Test of the Air-Cooled Finned-Tube Supercritical CO2 Sink Heat Exchanger.“ ASME. J. Thermal Sci. Eng. Appl. June 2019; 11(3): 031014 // https://doi.org/10.1115/1.4041686

- [12] Vojacek, Ales / Melichar, Tomas / Hájek, Petr / et al: „Experimental investigations and simulations of the control system in supercritical CO2 loop“, 3rd European Conference on Supercritical CO2 (sCO2) Power Systems, Paris, France, (02.10.2019), p. 89-104 // https://doi.org/10.17185/duepublico/48916

- [13] T. Hoppe, J. Braune, L. Nielsen: „Dynamic System Simulation for New Energy Markets - Optimization of a Coal Fired Power Plant Startup Procedure“ VGB PowerTech 9|2019 // Download (pdf)

- [14] Marcel Richter, Gerd Oeljeklaus, Klaus Görner: „Dynamic simulation of flexibility measures for coal-fired power plants”, VGB PowerTech 4|2020 // Download (pdf)